Contact UsCONTACT

Please feel free to contact us if you have any questions or concerns.

Inquiry FormStories

STORIES

SERIES EMBARK

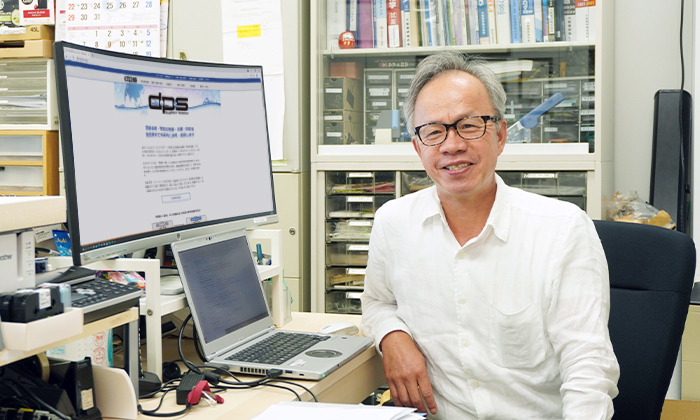

We are now entering an era in which both people and companies should be keenly aware of the SDGs (Sustainable Development Goals) and ESG (Environmental, Social, and Governance). Amid the demand for efforts to minimize the burden on nature and environmental sacrifices, DPS Corporation is engaged in research and development of products that meet the needs for recycling and higher purity by realizing high-performance and high-efficiency adsorption, separation, and recovery of trace metals and substances using its proprietary DualPore™ technology. DPS Inc. is engaged in the research and development of products that meet the needs for recycling and high purification. We interviewed Mr. Hongzhi Bai, CEO, who has a unique background as a cardiovascular surgeon, about the process from the start-up of the company to the present and the future. (Interviewer: Mae Kori)

I worked as a physician in cardiovascular surgery. Those were the days when catheters and balloons, which are now the standard of care, were the latest technology. I believe that medicine is truly an ever-evolving field, and the development of drugs and treatments is advancing day by day. However, while working as a doctor, I have always felt that Japan is a country where it is difficult to create new things from scratch, "ZERO to ONE. We are good at taking something that is already "ONE" in another country and brushing it up to make it more precise, but it is very difficult to create something new from scratch.

I really felt this especially when I was doing research at Stanford University and Harvard University in the United States. To my surprise, doctors are also involved in development and management as "chief medical officers" within companies. I found that very interesting when I saw it. In the U.S., many doctors worked for major pharmaceutical companies in various capacities, but in Japan, only a few doctors work for pharmaceutical companies. In Japan, however, there are only a few doctors in the pharmaceutical companies, so there is only a centralized relationship between the pharmaceutical companies and the doctors, as if the pharmaceutical companies are the manufacturers and the doctors are the users. In the U.S., however, doctors are involved in research and also in ventures directly related to that research, and the discovery that "doctors can also be involved in manufacturing" was truly eye-opening! It was an eye-opening discovery. I think this was what made me think about jumping into the venture business world. Later, I changed my position from "Dr. Haku(Bai)" to "Mr. Haku(Bai)," and at first it was hard to get used to it (laugh), but the job of creating and managing products directly related to my favorite research is exactly what I wanted, and now I feel that I am doing a very interesting job.

First, I worked for a company developing cell therapy and gene therapy in the U.S., where I was involved in development and even management, gaining experience and broadening my perspective. After returning to Japan, while working as vice president of a medical device development company, I came across a material called silica monolith, which was invented by a team led by Kazuki Nakanishi, a professor at Kyoto University (who also serves as a professor at Nagoya University). Silica monolith is a highly functional and advanced material that was created after a long period of research at Kyoto University. After further research, the silica monolith gel was pulverized and powdered into a wonderful material called "DualPore™," which is made from silica gel.

In the first place, the greatest appeal of silica gel was its wide versatility and immediate application in various industries, including medicine and food, since its safety is well established. We established this company in 2017 with the desire to "match this wonderful material with a variety of needs."

Our company name, DPS Inc. is an acronym for Dual Pore Solution. The name reflects our intention to solve social issues such as environmental problems (Solution) as a development-oriented company that makes full use of our core technology "DualPore™" and possesses flexible ideas and one-of-a-kind special technologies.

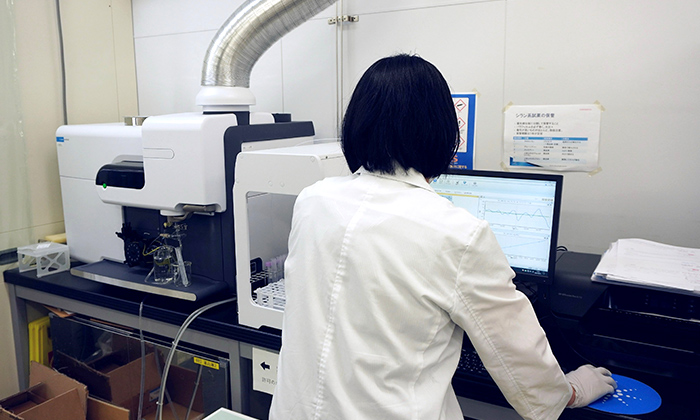

First, let us explain DualPore™. The particles that make up DualPore™ (hereafter referred to as "DualPore™ particles") have micro-scale (10-6 m) "through holes" in addition to the nano-scale (10-9 m) "pores" of conventional particles. Pores are the numerous dense pores inside the particles that adsorb, separate, and collect target substances. The combination of dual pore structure provides the particles with extremely high liquid permeability and effective specific surface area, which are its various advantages.

The DualPore™ Metal (Metal) Scavenger is an application of this "DualPore™" material in a ready-to-use cartridge. This product efficiently adsorbs and recovers trace metals remaining in solutions and waste liquids so that they can be reused or sold.

I believe that "trace amounts of rare metals in liquid waste are still a sleeping urban mine. Currently, one-third of the rare metals such as platinum, palladium, and rhodium consumed in Japan are recycled. However, this means that two thirds of them are still unclaimed. It is extremely wasteful that the majority of precious metals are discarded, and also undesirable in terms of the environmental impact of new mining to cover the discarded portion.

The "DualPore™ Metal (Metal) Scavenger" is ready-to-use with a general-purpose cartridge without the need for expensive high-pressure pumps or equipment. Not only can it recover precious and rare metals from large volumes of solutions and effluents from factories at concentrations as low as a few parts per million (ppm), which is considered difficult with conventional technology, but it can also concentrate and recover them at a rate approximately 80 times faster than conventional methods.

This product has already been adopted by several major companies, and we intend to further seek a wide range of business partners, including battery, electronics and appliance manufacturers, automotive and metal materials manufacturers, and others involved in rare metal recovery.

As I mentioned earlier, we would like to broadly invite specialized, strategic partners from various industries to expand the potential of this wonderful technology. Our basic policy is to first listen sincerely to the needs of our customers and then respond with solutions to those needs in the form of innovative products that apply our proprietary DualPore™ technology.

So how do we achieve this? It is true that we have really good and attractive material materials, but how to sell them? This is a business, so we must also improve our business performance. Because we are a business, we have to improve our performance and convince investment companies such as Kyoto-iCAP (Kyoto University Innovation Capital Co., Ltd.). While maintaining our commitment and love for manufacturing, we need to strategically consider the "selling points" of our products and promote them to the world. In addition, we must work hand in hand with business partners in various fields to create new products and expand our field.

To achieve this, I believe we will need salespeople who specialize in specialized fields, with expertise in science, chemistry, and technology, and who can also utilize marketing techniques. We will need people who can create scenarios for how to use and apply these wonderful materials with a flexible mind, and who can convey the appeal of our products with an eye not only to the SDGs but also to ESG issues, and get people interested in our products. I think it is an urgent need to develop such human resources.

Both Apple and Amazon were born from the idea of just one person. This is the power to create something unique from scratch. This may be something that Japanese people are not good at, but I believe that this "Zero to One" mindset is the driving force behind entrepreneurship. Starting a business is not an easy task, and of course, not everything will work out just because you have started a business. I myself always think, "First, break through the first point. Once you break through that point, you will always be able to see what comes next.

In terms of our work, we were first able to prove the extremely excellent permeability of the DualPore™ metal (metal) scavenger. Having made that breakthrough, we began to receive offers for joint development from various companies, and we are currently working on several of those projects. If we continue to make one breakthrough after another, companies will come forward to evaluate our research and technology and support us in the form of investment. Kyoto-iCAP always gives us opinions from a management perspective, which is very helpful for our company, which tends to focus more on research. I think this kind of calm investor's perspective is very important for a successful start-up.

I sense a strong desire among the younger generation in Japan today not to fail. In that sense, Japanese youth are quite conservative. But the world is really moving fast now. Whether it is the new Corona or economic trends, the future is still unclear. In such a chaotic situation, how do we show our identity, our Japaneseness, and our difference from others? What will be our selling point? Without such ideas, individuals, society, and the nation as a whole will probably just continue to wither away.

Starting a business is risky. However, I would like to encourage people who have an idea or conception that they think would be interesting to try, or who want to create something, to try it. I would like to encourage anyone who has an idea or conception that they think would be interesting to try, or anyone who wants to create something, to give it a try. Of course, it is your own responsibility, but failure is not something to be avoided or simply feared. Failure is the step that leads to the next step. In other words, without failure, there is no progress or growth.

The appeal of a venture business is that you can move forward while stepping up and directly feeling the response. Of course, I have responsibilities to my employees and investors, and there are many headaches when it comes to business management, but I find it very rewarding to develop what I like, commercialize it, sell it, and apply and develop it in partnership with other companies. Our goal is to play a role in solving global-scale problems by developing and spreading the wings of one-of-a-kind technologies born from the concept of "ZERO to ONE. In the near future, it would be interesting to work with the younger generation who are not afraid of failure and are willing to take on challenges, and to further develop our work in a flexible and bold manner.

(Interviewed in August 2021. Affiliations, positions, etc. are as of the time of the interview)

President Bai has been working on the commercialization of silica monoliths since 2007 and has found numerous applications that other materials cannot. In response to the increasing need to recycle rare metals in recent years, he has commercialized palladium recovery and has begun shipping products.

A start-up company in which entrepreneurs, with a strong desire to help solve social issues, are drawing on the potential of new materials created at Kyoto University.

Kenichi Yotsumoto

DPS Inc. Website

Please feel free to contact us if you have any questions or concerns.

Inquiry Form